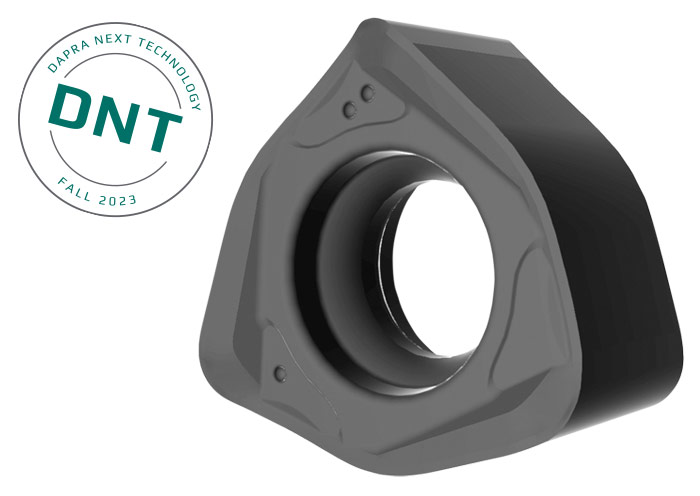

New VAPOR™ TRI-X2™ High-Feed Inserts

VAPOR High-Feed is now optimized for materials and applications that demand the DAPRA “D” geometry.

If you struggle to maximize metal removal rates when machining stainless steel and high-temp alloys, here's the news you've been waiting for. The VAPOR high-feed milling platform is now optimized for materials and applications that demand the DAPRA "D" insert geometry.

VAPOR's double-sided trigon TRI-X2™ inserts provide six usable edges and are now available in our "D" geometry for honed high-shear cutting action and reduced tool pressure. Manufactured from DMM25 micro-grain carbide with UHT Ultra-High-Temperature coating, these new inserts minimize temperature build-up and help deliver maximum feed rates in these challenging materials.