Resources

Shop by Category

Technical Articles & Application Tips

Dapra Indexable Milling Tech Tips

Technical Articles & White Papers

Tool Manufacturer Commits to Marketing-Free Model for Product Training Seminars

For several years Dapra Corp. has had a technical center in Rockford, Illinois, where, like many other OEMs, the cutting tool manufacturer has conducted training sessions there for its end users and distributors. Recently, Dapra changed its seminar model to focus less on marketing, and more on technical training.

Appeared in Modern Machine Shop®, March 2017 – Copyright © Gardner Business Media, Inc. 2017, used with permission.

Analyze This: Examining a cutting tool’s performance values, not just its cost, reveals the true efficiency of machining processes.

Question: "How long should this cutting tool last?" Answer: "How long do you want it to last?" Examining a cutting tool's performance values, not just its cost, reveals the true efficiency of machining processes.

Appeared in MoldMaking Technology®, October 2016 – Copyright © Gardner Business Media, Inc. 2017, used with permission.

Low Cost vs. Real Cost: What is the real cost of a cutting tool when it is applied? Carefully controlled tests provide the answer.

One of the perennial issues in metalworking is the cost of cutting tools. Many tool manufacturers promote low-cost tools or "free" cutters with the purchase of inserts with the idea that their use can save shops money. However, what shops should be asking is: "What is this free cutter actually costing me?" or, "Is this cheap insert really saving me money?"

Appeared in Cutting Tool Engineering®, September 2010 – Copyright 1995-2010, used with permission.

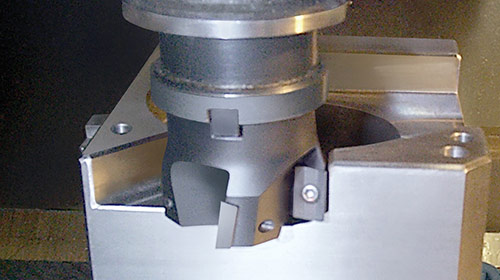

Solving the Roughing Equation: To make a good choice between square shoulder and button cutters for your roughing operation, keep their strengths and limitations in mind.

Looking at your next project, you evaluate the material removal required on the job. The workpiece requires extensive roughing, with complex surfaces and shapes remaining for finish machining. Your machine has oodles of horsepower, but not exactly industry-leading feed capability. The question on your mind at this point is: "How can I rough this part without losing valuable time or creating extra work in the finishing process?"

Appeared in Manufacturing Engineering® – Copyright by the Society of Manufacturing Engineers, used with permission.

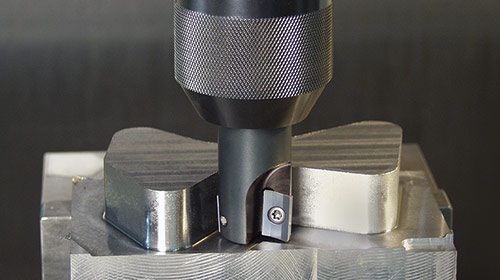

The Case for Copy Milling Cutters: The round-insert "button cutter" can bring a high metal removal rate to a low horsepower machining center.

The work of indexable milling tools is often accompanied by vibration that is a familiar sound — and a familiar feel — in many shops. When these tools are run at heavy depths of cut to achieve high metal removal rates, the productivity may come at the expense of the corner of the cutting tool and the life span of the machine. One alternative that can provide a smoother cut, in addition to many expanded capabilities, is the copy mill. "Button cutter" is another name for this type of tool.

Appeared in Modern Machine Shop® – Copyright © Gardner Business Media, Inc., used with permission.

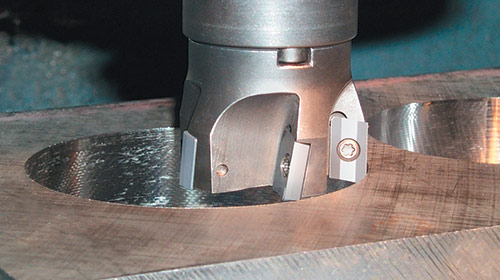

Using Helical Interpolation to Make Larger-Diameter Holes

Producing a large-diameter hole is a common application for many shops, and there are numerous methods that can be used to achieve the end result. However, there are often numerous obstacles to completing the process cost-effectively. Horsepower consumption is frequently a concern in these types of applications, especially on the more common 20 horsepower and below machine tools. These machines are capable of high speeds and feeds, but rigidity is sacrificed to the extent necessary to accomplish the quick movements. Using conventional means, making large-diameter holes is hard on the machine tool and the cutting tools involved. This fact has created the demand for a smoother method of making these holes that stays within the cycle times necessary to be competitive. EWT Incorporated (Rockford, IL) has dramatically improved its hole-making capabilities utilizing helical interpolation. The concept was introduced to them by Dapra Corporation (Bloomfield, CT) in an effort to improve cycle times on a new part.

Appeared in Modern Machine Shop® – Copyright © Gardner Business Media, Inc., used with permission.