Resources

Shop by Category

Loading...

Common Formulas for Milling Operations

Calculate RPM, IPM, SFM, IPT and more.

Below are variable abbreviations and formulas for many common milling operations.

Click here to download a printable PDF file containing these formulas.

Looking for speed & feed calculators and recommendations for your Dapra tooling? Click here for our extensive library of free resources, or contact an applications specialist to discuss the optimal parameters for your milling program.

Variables / Abbreviations

- Speed – Surface Feet per Minute (SFM)

- Feed – Inches per Minute (IPM)

- Feed per Tooth (FPT)

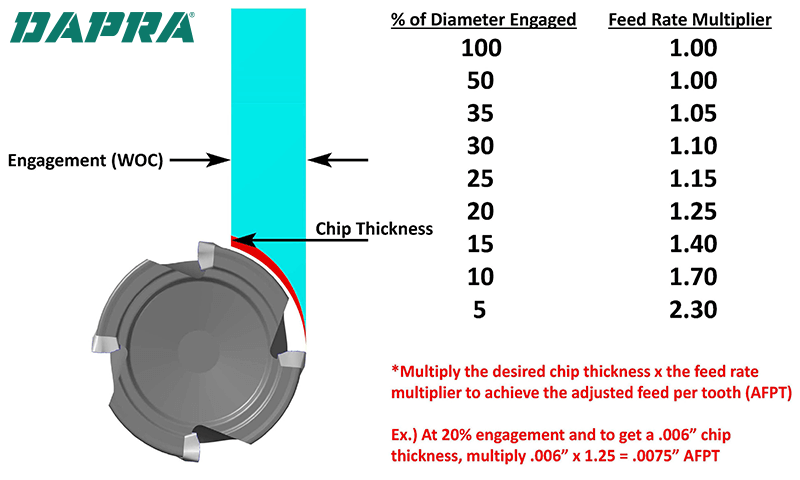

- Adjusted Feed per Tooth – Chip Thinning (AFPT)

- Feed per Revolution (FPR)

- Depth of Cut (DOC)

- Width of Cut (WOC)

- Tool Diameter (D)

- # of Teeth in Cutter (Z)

- Metal Removal Rate – Cubic Inches per Minute (MRR)

Milling Formulas

- Speed (RPM) = (SFM x 3.82) / D

- Feed (IPM) = RPM x FPT x Z

- SFM (Surface Feet per Minute) = (RPM x D) / 3.82

- IPT (Inches per Tooth) = (IPM / RPM) / Z

- MRR (Cubic Inches per Minute) = IPM * WOC * DOC

- AFPT (@ less than 1/2 dia. WOC) = IPM x sqroot of (D / WOC)

- HP (Horsepower Consumption) = MRR x mf

- mf - steel = 1

- mf - gray iron = .65

- mf - aluminum = .3

- * - 1.5% from total for every degree positive

For lead angle (chip thinning) and effective cutting diameter compensation, see corresponding tool reference page / catalog.

Sign Up below for updates to our Milling Training Series. Whether you sell or use our tools, you fill find these videos of value. We provide an overview of the processes and straight forward comparisons to different tooling options.

Our objective in these videos is to help people at all levels understand the process and applications better.