Vapor™ Double-Sided High-Feed Milling Platform

Developed for lighter, faster cutting, capitalizing on modern high-feed machining principles.

Vapor delivers extreme metal removal rates by combining low depth of cut and high feeds per tooth, with reduced vibration tendencies on long-reach tools. New TRI-X2™ double-sided trigon inserts provide six usable edges to reduce your overall manufacturing costs.

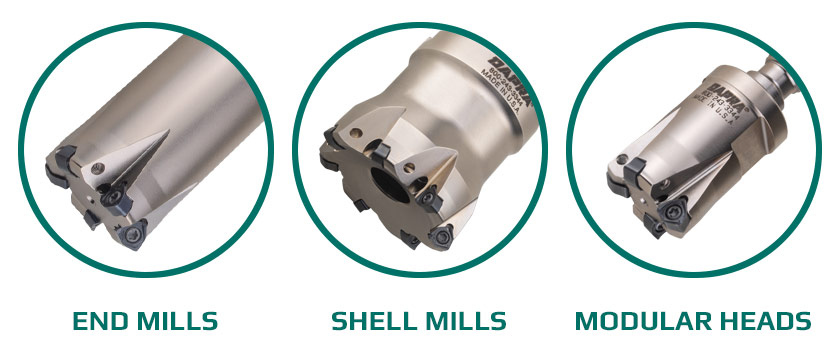

Cutter Bodies

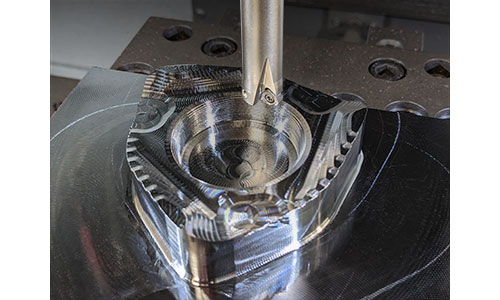

Vapor end mills, shell mills, and modular heads are machined from highly shock-resistant, through-hardened steel for proven performance in aerospace, automotive, energy, firearm, medical, mold & die, and general industrial high-feed milling applications.

- Diameter range of .500" - 2.000", with up to 7 flutes

- Through-coolant holes for maximum temperature control and chip evacuation

- Re-engineered gullets and insert pockets provide more effective chip evacuation and better redistribution of cutting forces, improving tool stability and overall tool life

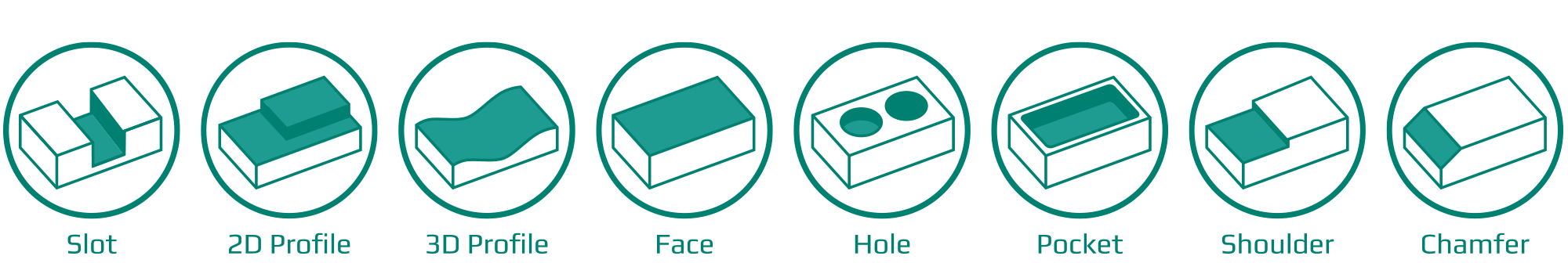

- Tuned entry angle and positive rake allow for most efficient tool paths for ramping, pocketing, plunging, and shoulder/face milling operations

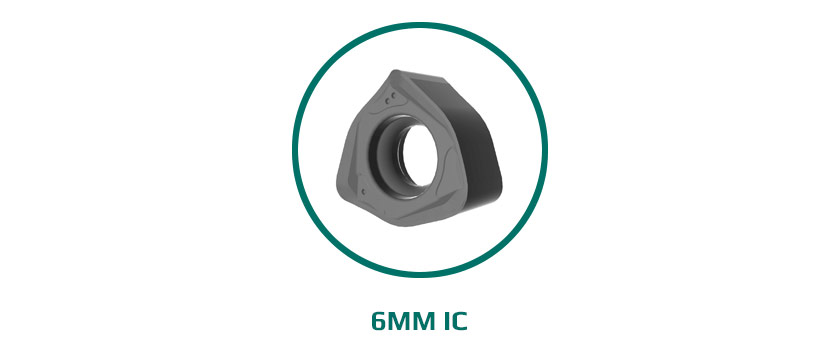

Inserts

TRI-X2 6mm double-sided trigon inserts provide six usable edges reduces overall cost per insert edge. Best-in-class insert screw size provides outstanding longevity and allows for easy indexing.

- Addition of a radial cutout for improved chip evacuation

- Improved edge geometry now available in both strong ("T" edge) and sharp ("D" edge) configurations

- Available in proven base grades, with advanced coating technology for superior performance