High-Feed Ramping

An ultra-fast, versatile, economical approach for profile milling applications

Plunge. Lead in. Profile. Lead out. Repeat until reaching final depth. Profile milling does not have to be this inefficient! As you'll see here while machining 4140PH, high-feed ramping with Dapra's indexable tooling allows you to rough in your part profile much more quickly.

By starting directly on the part profile and executing a constant ramp in the Z-axis, you'll eliminate time-wasting entry and exit moves and achieve MRR that rivals high-efficiency milling. All without the cost of solid carbide end mills.

Our high-feed tools are indexable, eliminating changes in part size due to resharpening and providing a low initial cost compared to solid carbide tools. And all of these cuts can be run at identical parameters in long-reach applications with a 2x or 3x length-to-diameter ratio – you aren't restricted by the flute length of your end mill.

Learn more about our indexable high-feed tooling.

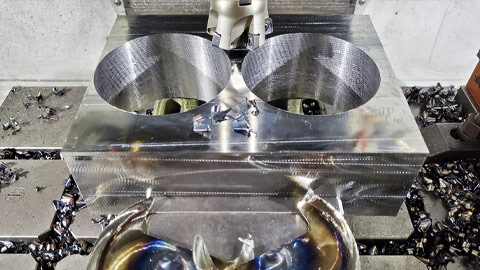

The features machined in this demo – hole helix, elongated radial slot, triangular lightening pocket, and 2D contour with a large cutout – are just the tip of the iceberg for what you can achieve with the high-feed ramping approach.

Learn more about high-feed ramping

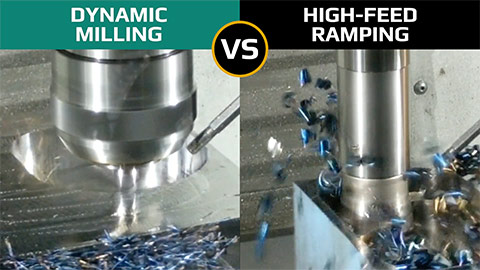

High-efficiency milling vs. high-feed ramping

Dynamic milling with a solid carbide end mill is all the rage, but you may be able to match – or beat – those removal rates and save significant money on tooling by ramping with indexable high-feed tooling.

Efficiently machining large-diameter holes

Forget time-consuming starter holes and step cuts. High-feed helixing can shorten cycle times for large-diameter hole making to never-before-seen levels – even on a 40-taper machine.

High-feed ramping for outside profile contour milling

Detailed instructional video comparing three methods for outside profile contour milling: high-feed ramping, high-efficiency milling and 2D step-down profile milling. See how to program each method, compare cycle times, and view demo footage of high-feed ramping on a Haas 40-taper VM2.

Pocket roughing comparison: high-feed ramping vs. high-efficiency milling

This detailed instructional video compares several approaches to a typical pocketing application: high-feed constant profile ramping (with both an end mill and shell mill) and dynamic milling with a solid carbide end mill. Learn how to program each approaches and compare actual cycle times.

Have questions about implementing this approach?

Get more tech tips!

Join our email list or follow our social channels for regular tech tips. Need assistance with your application? Contact one of our technology specialists to review your parameters.

Choose the best indexable tooling the first time – every time

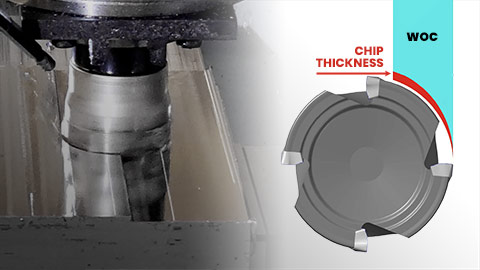

Choose the best indexable tooling the first time – every time Maximize feed rate with radial chip thinning

Maximize feed rate with radial chip thinning