Dynamic Milling vs. High-Feed Ramping

Dynamic milling – or high-efficiency milling – is very popular for modern roughing applications. It allows for excellent metal removal rates and good tool life, and dynamic tool paths are becoming easier to program thanks to CAM system updates.

However, the solid carbide tooling it requires is very expensive, and machining depth is limited to the flute length of the end mill. You can overcome these challenges with high-feed ramping, an alternative approach using cost-effective indexable carbide tooling that is ideal for both short and long-reach applications.

What is high-feed ramping?

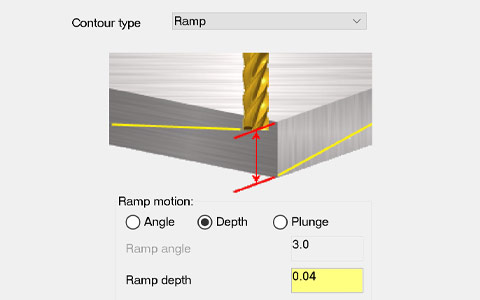

High-feed ramping is simply profile milling any typical two-dimensional shape with the addition of a simultaneous ramp in the Z-axis. Most CAM systems offer this approach as a standard tool path.

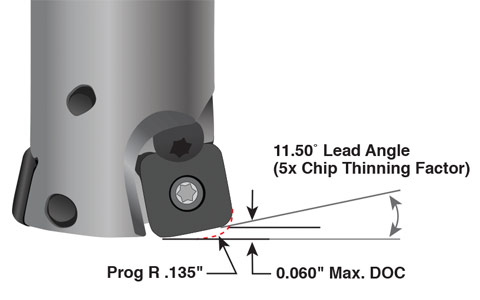

The depth of cut is light, but the feed rate is typically hundreds of inches per minute, achieving outstanding MRR that is very competitive with dynamic milling – without the high tooling cost. A worn cutting edge is indexed rather than requiring replacement like a carbide end mill, resulting in significant cost savings.

Since high-feed ramping is an axial-directed cut – or into the spindle – it is not limited by tool length as dynamic milling is. This makes the high-feed ramping approach very attractive for machining deep pockets or profiles.

Tips for successful ramping with indexable cutting tools

Easy to program using the ramp option in your CAM software profile milling tool path.

Use strong air blast or high-pressure coolant to evacuate chips, especially when pocketing.

Keep ramp depth within the maximum depth of cut for your high-feed insert.

Have questions about implementing this approach?

Learn more about high-feed ramping

What can you do with high-feed ramping?

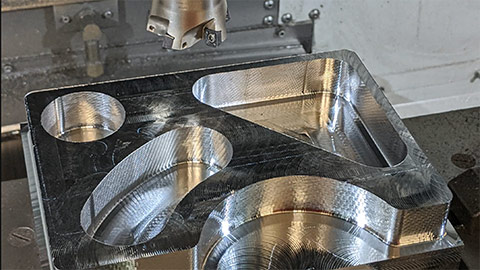

See the versatility and efficiency of high-feed ramping as we machine a 4140PH workpiece on a Haas 40-taper VM2. Check out ultra-fast machining of a hole helix, elongated radial slot, triangular lightening pocket and 2D contour with large cutout.

High-feed ramping for outside profile contour milling

Detailed instructional video comparing three methods for outside profile contour milling: high-feed ramping, high-efficiency milling and 2D step-down profile milling. See how to program each method, compare cycle times, and view demo footage of high-feed ramping on a Haas 40-taper VM2.

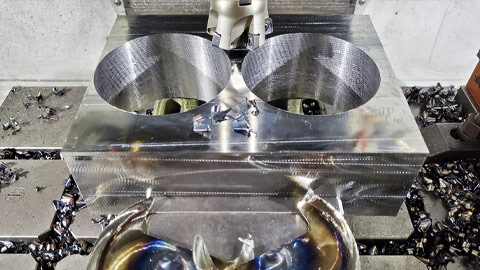

Efficiently machining large-diameter holes

Forget time-consuming starter holes and step cuts. High-feed helixing can shorten cycle times for large-diameter hole making to never-before-seen levels – even on a 40-taper machine.

Pocket roughing comparison: high-feed ramping vs. high-efficiency milling

This detailed instructional video compares several approaches to a typical pocketing application: high-feed constant profile ramping (with both an end mill and shell mill) and dynamic milling with a solid carbide end mill. Learn how to program each approaches and compare actual cycle times.

Get more tech tips!

Join our email list or follow our social channels for regular tech tips. Need assistance with your application? Contact one of our technology specialists to review your parameters.

Choose the best indexable tooling the first time – every time

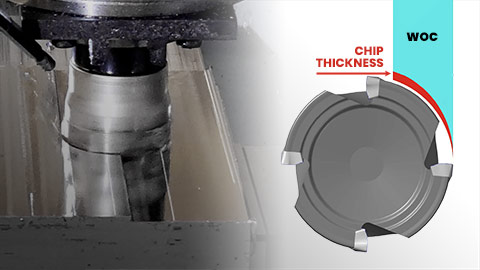

Choose the best indexable tooling the first time – every time Maximize feed rate with radial chip thinning

Maximize feed rate with radial chip thinning