High-Feed Milling

Extra-tough high-feed tool series

Single-Sided Insert Platform

- High-Feed Cutter Bodies

• Through-hardened, extra-tough tool steel for optimum strength

• Surface hardened for extra wear and chip-welding resistance

• Machined after hardening for excellent runout

• Standard and long-reach bodies available

High-Feed Inserts

• Strong design allows high feed rates in all materials

• Positive clearance provides excellent ramping and helixing

• Multiple geometries for smooth or strong edge conditions

• Grade variety provides strong performance in all materials

.jpg)

.jpg)

Mid-feed inserts have a stronger cross-section than the mini-feed, but are smaller than the heavy-feed.

10mm Series Single-Sided High-Feed Tooling

1.000" - 3.000" OD

Double-Sided Insert Platform

VAPOR™ insert technology includes a positive cutting edge and extra bottom clearance for a smooth chip flow and excellent ramping capability for a double-sided insert. All edges are labeled with “dots” or “dashes” to aid in indexing accuracy.

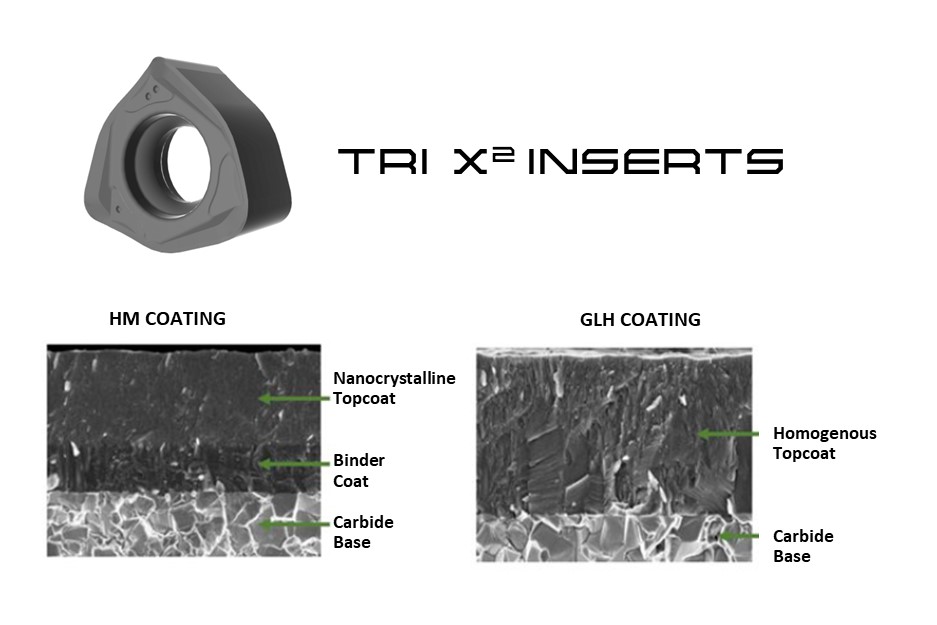

VAPOR™ Tri-X2 inserts include dedicated grades and geometries for a wide range of materials.

› “T” geometry for steels, irons, hardened steels

› “D” geometry for stainless steels, high-temp alloys

.png)

How does it work?

High-feed milling creates significant chip thinning due to an extreme lead angle. Feed rates must compensate for this to maximize productivity. The figure at left shows an example of this condition.

Adjusting feed rates to account for chip thinning creates cutting conditions that provide very high feeds (IPM), but at lighter depths of cut (DOC). See the specific operating instructions for each size of high-feed insert to optimize these cutting tools.

Product Line Details

Application Support

High-Feed Video Playlist

Dozens of Training Videos for all Levels

.jpg)

.jpg)