Shop by Category

Operating Instructions for RHINO-FEED™ High-Feed Inserts

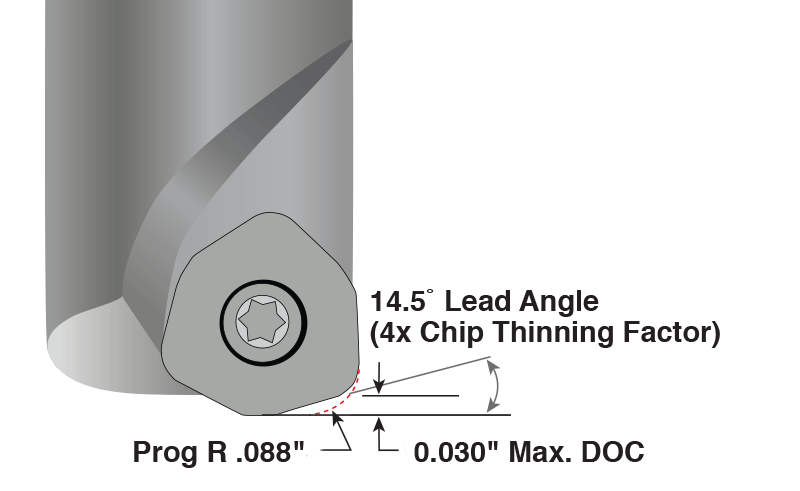

Operating Instructions for Mini-Feed Inserts

Mini-feed inserts have the smallest IC (inscribed circle) and smallest cross section. It is suggested to run a good common-sense combination of feed and DOC with these inserts. When running a light DOC, the higher end of the feed range is acceptable. When running heavier DOC, use the lower to middle feed ranges. Index inserts promptly upon visible wear to avoid breakage.

If cutting at .025" DOC and trying for a .007" chip thickness, multiply .007" x 4 = .028" FPT.

Compensated FPT:

Dapra's mini-feed inserts have a 4x chip thinning factor. The compensated FPT recommendation of .012-.032" represents an actual chip thickness of .003-.008".

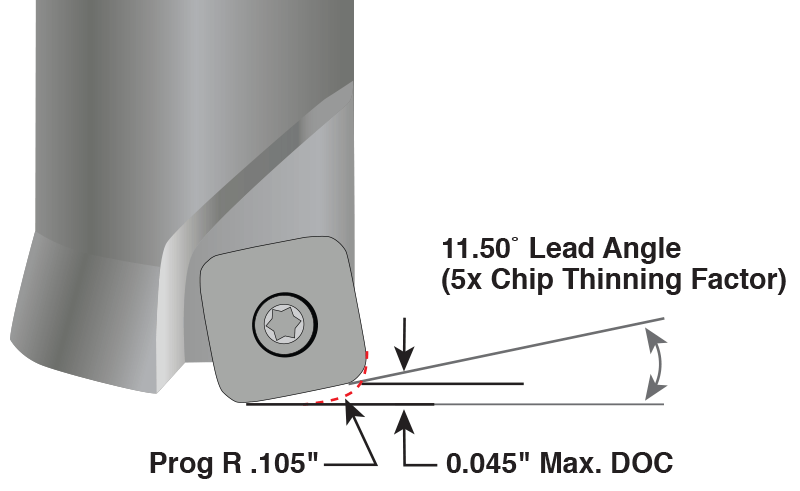

Operating Instructions for Mid-Feed Inserts

Mid-feed inserts have a stronger cross-section than the mini-feed, but are smaller than the heavy-feed. These are great general-purpose inserts best suited for lighterduty (40-taper, linear ways, etc.) machines. Run faster feeds with lighter DOC in most situations. In heavier DOC, run the lower to middle area of the feed ranges.

If cutting at .030" DOC and trying for a .010" chip thickness, multiply .010" x 5 = .050" FPT.

Compensated FPT:

Dapra's mid-feed inserts have a 5x chip thinning factor. The compensated FPT recommendation of .020-.060" ("T") and .015-.050" ("D") represents an actual chip thickness of .004-.012" and .003-.010", respectively.

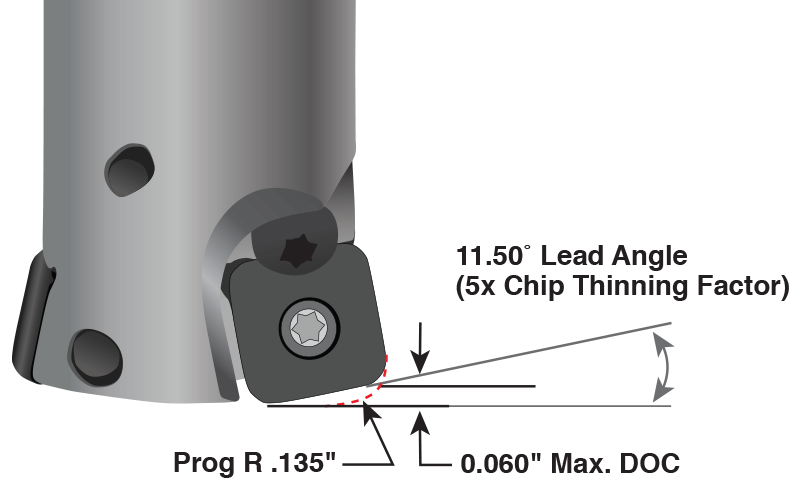

Operating Instructions for Heavy-Feed Inserts

Heavy-feed inserts have the strongest cross-section of the RHINO-FEED line. Heavy-feed inserts are suitable for heavier DOC and larger machines (50-taper, box ways, etc). For optimum performance, use good combinations of heavier DOC with light-to-middle FPT, or lighter DOC with heavier FPT.

If cutting at .030" DOC and trying for a .010" chip thickness, multiply .010" x 5 = .050" FPT.

Compensated FPT:

Dapra's heavy-feed inserts have a 5x chip thinning factor. The compensated FPT recommendation of .025-.070" ("T") and .020-.055" ("D") represents an actual chip thickness of .005-.014" and .004-.011", respectively.