Shop by Category

Loading...

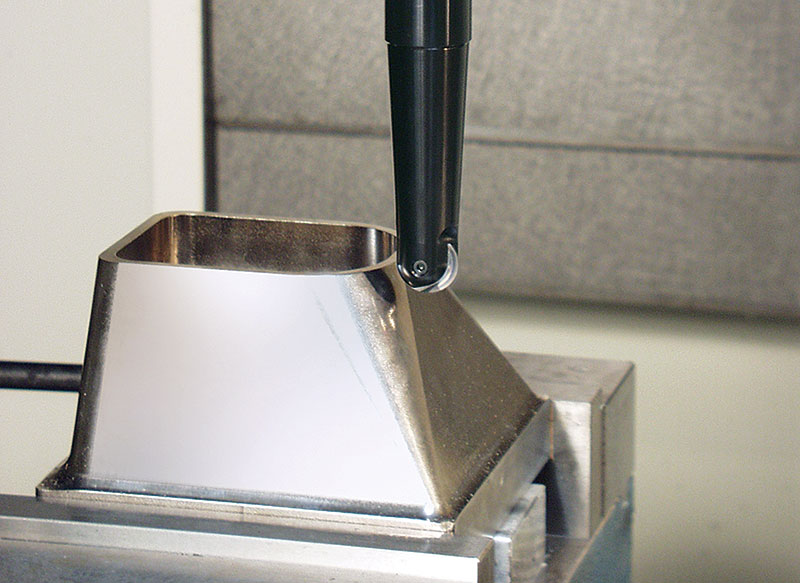

Ball Nose Finishing Application Information

Ball Nose Technical Considerations

- Always use anti-seize compound on threads and screw body.

- Thoroughly clean pocket and screw at each insert change.

- Change insert screw every 10 inserts.

- Use high quality tool holders for rigidity and concentricity: milling chucks, heat-shrink and mechanical shrink holders are recommended; collets and end mill holders are not recommended.

- Cutter bodies will wear and fatigue over time; inspect tool before each use.

Recommendations for Finish Milling

- Maximum Depth of Cut (DOC) for finishing should be less than or equal to 10% of ball diameter.

- Stepover should be greater than or equal to DOC.

- Ball nose tools are not designed for roughing. Use high-speed machining techniques (light DOC and high feed rates) for stable and fast cuts where greater metal removal is required.

- Climb milling is preferred.

- When plunging with Ball Nose, use pecking cycle with a maximum of .002" FPT; maximum recommended depth is 30% of ball diameter.

- Back Draft and Flat Bottom Inserts are not designed for plunging; ramp in at a maximum angle of 2°.

- Compensate for Effective Cutting Diameter (see Feed, Speed & Diameter Compensation).

- Compensate for chip thinning with Feed Rate Adjustment (see Feed, Speed & Diameter Compensation).

- Surface finish (RMS) is a function of stepover and feed per tooth.

- Try to work within recommended surface footage and chip loads.

- Decrease feed rate coming into corners to reduce chatter.

- For long-reach applications, utilize the Carbide Shank/Carbide Core cutting tools for increased rigidity and reduced chatter.