Shop by Category

Loading...

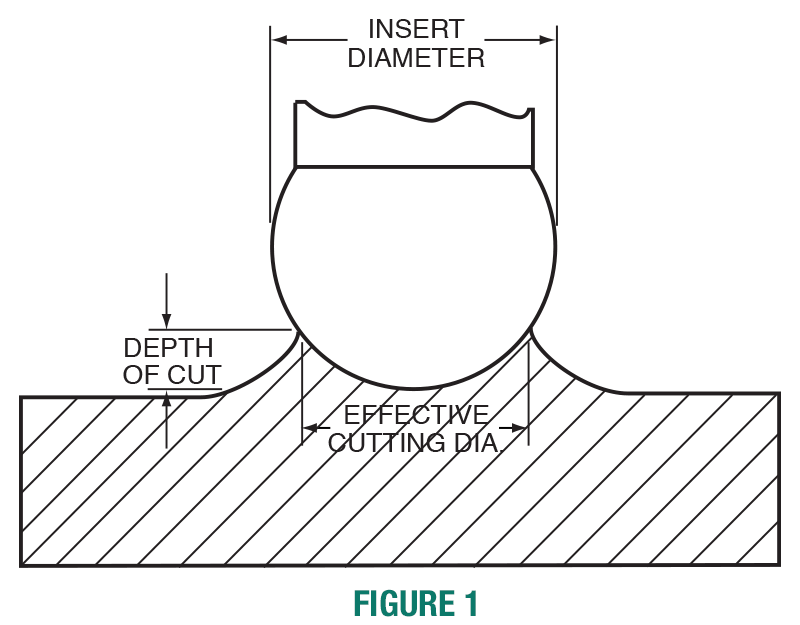

Feed, Speed & Diameter Compensation for Ball Nose Finishing Mills

Table 1: Effective Cutting Diameter (ECD)

| Depth of Cut (DOC) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Insert Diameter | .005 | .010 | .015 | .025 | .035 | .050 | .100 | .125 | .150 | .200 | .250 | |

| .250 | .070 | .098 | .119 | .150 | .173 | .200 | .245 | .250 | ||||

| .375 | .086 | .121 | .147 | .187 | .218 | .255 | .332 | .354 | .367 | .374 | ||

| .500 | .099 | .140 | .171 | .218 | .255 | .300 | .400 | .433 | .458 | .490 | .500 | |

| .625 | .111 | .157 | .191 | .245 | .287 | .339 | .458 | .500 | .534 | .583 | .612 | |

| .750 | .122 | .172 | .210 | .269 | .316 | .374 | .510 | .559 | .600 | .663 | .707 | |

| 1.000 | .141 | .199 | .243 | .312 | .368 | .436 | .600 | .661 | .714 | .800 | .866 | |

| 1.250 | .158 | .223 | .272 | .350 | .412 | .490 | .678 | .750 | .812 | .917 | 1.000 | |

- Select diameter of tool to be used.

- Determine Depth of Cut (DOC) to be used.

- Refer to Figure 1 and Table 1 to find the Effective Cutting Diameter (ECD).

- Refer to the Ball Nose Feed and Speed chart (PDF) to select the surface footage to be used (SFM).

- Calculate RPM using the ECD and SFM. (SFM x 3.82 / ECD = RPM)

- Refer to Table 2 to determine Feed Rate Adjustment (FRA).

- Refer to the Feed and Speed chart (PDF) to select Feed per Tooth (FPT). Calculate Inches per Minute (IPM). (RPM x FPT x FRA = IPM)

Table 2: Feed Rate Adjustment (FRA)

| Insert Diameter | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Depth of Cut (DOC) | 1/4" | 5/16" | 3/8" | 1/2" | 5/8" | 3/4" | 1" | 1-1/4" | |

| .005 | 3.6 | 4.0 | 4.4 | 5.0 | 5.6 | 6.1 | 7.1 | 7.9 | |

| .010 | 2.6 | 2.8 | 3.1 | 3.6 | 4.0 | 4.4 | 5.0 | 5.6 | |

| .015 | 2.1 | 2.3 | 2.6 | 2.9 | 3.3 | 3.6 | 4.1 | 4.6 | |

| .020 | 1.8 | 2.0 | 2.2 | 2.6 | 2.8 | 3.1 | 3.6 | 4.0 | |

| .025 | 1.7 | 1.8 | 2.0 | 2.3 | 2.6 | 2.8 | 3.2 | 3.6 | |

| .050 | 1.2 | 1.4 | 1.5 | 1.7 | 1.8 | 2.0 | 2.3 | 2.6 | |

| .075 | 1.1 | 1.2 | 1.2 | 1.4 | 1.5 | 1.7 | 1.9 | 2.1 | |

| .100 | 1.1 | 1.1 | 1.2 | 1.4 | 1.5 | 1.7 | 1.8 | ||

| .125 | 1.1 | 1.2 | 1.3 | 1.3 | 1.5 | 1.7 | |||

| .150 | 1.1 | 1.2 | 1.3 | 1.4 | 1.5 | ||||

| .175 | 1.1 | 1.2 | 1.3 | 1.4 | |||||

| .200 | 1.1 | 1.3 | 1.4 | ||||||

| .250 | 1.2 | 1.2 | |||||||

| .300 | 1.1 | 1.2 | |||||||

| .400 | 1.1 | ||||||||

Use multiple above to calculate adjusted feed rate.