Shop by Category

Arnold High-Pressure Machine Vises

Controllable power and dependable clamping.

Arnold vises, manufactured by world-leader Fresmak and represented in the USA by Dapra, offer high-pressure workholding solutions that are suitable for milling, grinding, drilling, toolroom and production work. All Arnold vises are manufactured to precision tolerances and accurate standards to ensure reliability and long life.

They combine a heavy-duty, rugged design with precision manufacturing and the highest quality materials available to give the best value to our customers.

Arnold Classic – HydraVise

- Up to 18,000 lbs. pressure in 4 size vises: 3.5", 5.0", 6.5" and 8" jaw widths

- Hydraulic and mechanical spindles available

- Normal and narrow vise bases (for close mounting)

Arnold MAT

- Fully-ground periphery guarantees parallelism and perpendicularity for side and end mounting

- High-pressure pull-down clamping provides ultimate security and accuracy

- Built-in rear jaw for strength and stability

- Hydraulic and mechanical versions with up to 11,000 lbs. pressure in 3.5", 5.0", 6.5" and 8" jaw widths

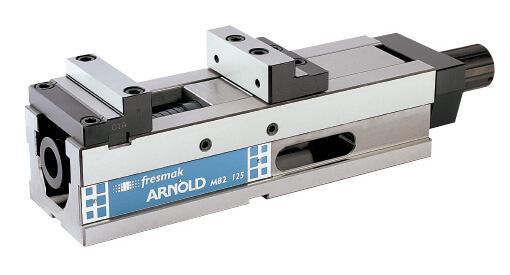

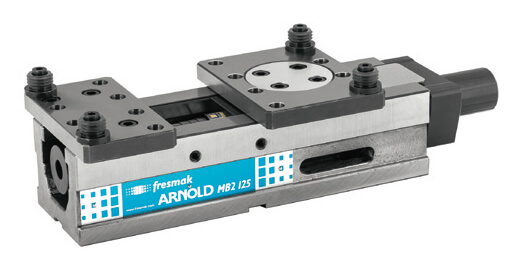

Arnold MB2

- Top-bottom ground version of MAT vise – economy model

- Interchangeable front and rear jaws for optimum versatility

- Hydraulic and mechanical versions with up to 11,000 lbs. pressure in 5.0" and 6.5" jaw widths

Arnold Durmak

- MB2 clamping capacity with better clamping variability

- One fixed and one moving jaw, flat for adding clamping fixtures/grippers

- Mechanical intensifier provides up to 11,000 lbs. pressure in 5" and 6.5" jaw widths

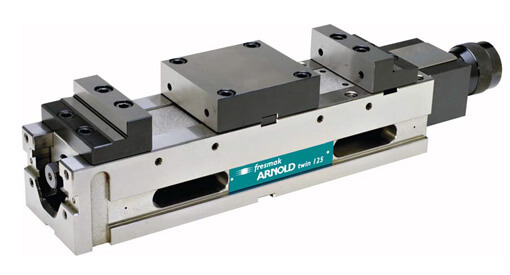

Arnold Twin

- High-pressure clamping of two workpieces simultaneously

- 3rd-hand feature allows clamping of each piece in two stages

- Fully-ground periphery guarantees parallelism and perpendicularity for side and end-mounting

- Hydraulic intensifier provides up to 11,000 lbs. pressure in 3.5" and 5.0" jaw widths

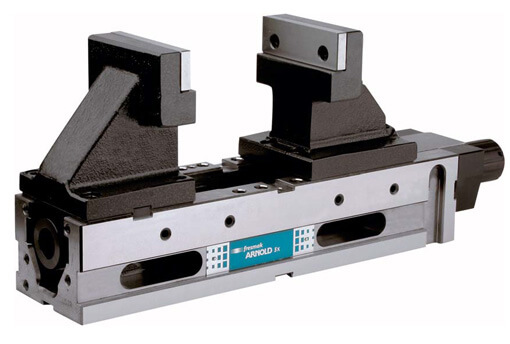

Arnold 5X Vise for 5-Axis Machining

- Tall jaws for 5-axis machining

- Mechanical intensifier provides up to 6,600 lbs. clamping pressure

- 5.0" jaw width on two different length vise bodies (medium and long)

- Large opening accepts workpieces up to 9.5" long

Arnold SC Self-Centering Vise

- Self-centering vise without high-pressure clamping

- High-mount screw maximizes clamping force and minimizes jaw deflection

- Centering accuracy .0007"

- Small footprint suitable for 5X machining in jaw widths of 2.75", 3.5" and 5.0"

Arnold SC 5X

- Self-centering vise without high-pressure clamping

- Tall jaws for optimum 5X access

- High-mount screw maximizes clamping force and minimizes jaw deflection

- Centering accuracy .0007"

- Small footprint suitable for 5X machining in jaw widths of 3.5" and 5.0"

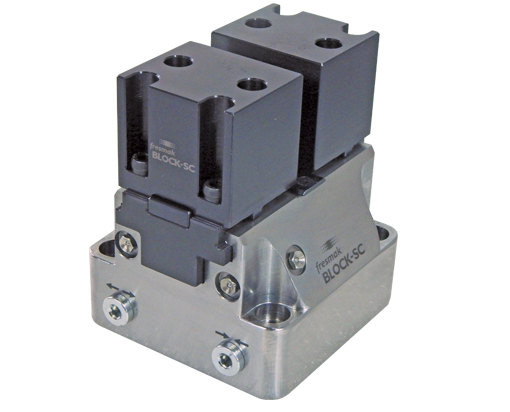

Fresmak Block-SC Hydraulic

- Hydraulic static blocks reach a pressure between 16 to 40 KN with an infeed power of 20 bar

- 0.24" and 0.31" stroke range

- Repeatability accuracy: 0.0008"

- Hydraulic supply up to 120 bar

Fresmak Block-SC Pneumatic

- Pneumatic static blocks reach a pressure between 8 to 20 KN with an infeed power of 6 bar

- 0.24" and 0.31" stroke range

- Repeatability accuracy: 0.0008"

- Pneumatic supply up to 9 bar

Need help selecting the best vise for your application?

Remember, your job is our job! We're here to help you choose the correct equipment and tooling to maximize your efficiency and productivity.

Fresmak has specialized in vises and clamping devices since 1967. A highly qualified team and emphasis on research and development have made Fresmak a world leader in vise manufacture.