Shop by Category

Toroid Feed Rate Compensation

Feed Rate Compensation (Round Inserts)

After determining the desired chip thickness (FPT – see Recommended Cutting Speeds chart PDF), find the insert diameter and Depth of Cut intersection in the chart at right. Multiply the desired chip thickness by the factor shown in the chart below. This will be the Adjusted Feed per Tooth (AFPT), resulting in a true chip thickness of the desired amount.

Example:

If using a 1" Toroid end mill with the 1/2" inserts @ .03" Depth of Cut (DOC), the factor for the chip thickness = 2.1. So, if a chip thickness of .005" is desired, a feed rate of .0105" (.005 x 2.1) needs to be programmed into the machine tool.

Or:

Adjusted Feed per Tooth (AFPT) = chip thickness x chip thinning factor (from chart)

| Insert Diameter | |||||

|---|---|---|---|---|---|

| Depth of Cut (DOC) | 3/8" | 1/2" | 5/8" | 3/4" | |

| 0.005 | 4.4 | 5.0 | 5.6 | 6.1 | |

| 0.010 | 3.1 | 3.6 | 4.0 | 4.4 | |

| 0.015 | 2.6 | 2.9 | 3.3 | 3.6 | |

| 0.020 | 2.2 | 2.6 | 2.8 | 3.1 | |

| 0.025 | 2.0 | 2.3 | 2.6 | 2.8 | |

| 0.030 | 1.8 | 2.1 | 2.3 | 2.6 | |

| 0.035 | 1.7 | 2.0 | 2.2 | 2.4 | |

| 0.040 | 1.6 | 1.8 | 2.0 | 2.2 | |

| 0.050 | 1.5 | 1.7 | 1.8 | 2.0 | |

| 0.060 | 1.4 | 1.5 | 1.7 | 1.8 | |

| 0.075 | 1.3 | 1.4 | 1.5 | 1.7 | |

| 0.085 | 1.2 | 1.3 | 1.5 | 1.6 | |

| 0.100 | 1.1 | 1.3 | 1.4 | 1.5 | |

| 0.125 | 1.1 | 1.2 | 1.3 | 1.3 | |

| 0.150 | NR | 1.1 | 1.2 | 1.3 | |

| 0.180 | NR | NR | 1.1 | 1.2 | |

| 0.200 | NR | NR | NR | 1.1 | |

| >0.200 | NR | NR | NR | NR | |

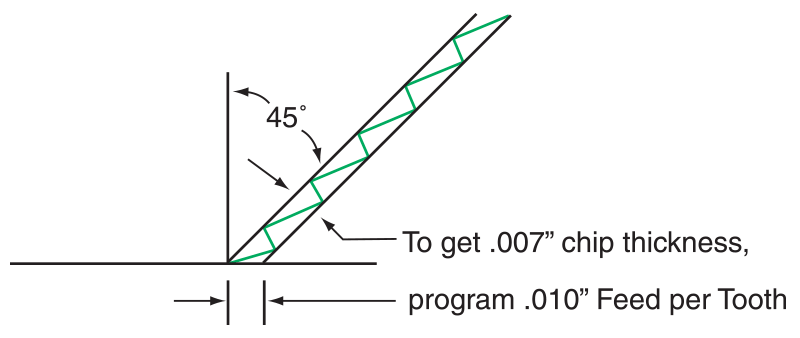

Compensation for 45° Lead Angle (Octagonal Inserts)

For all Depths of Cut:

Multiply desired chip thickness by 1.4 for Adjusted (programmed) Feed per Tooth (AFPT).

Example:

For .007" chip thickness, feed @ .010"

(.007 x 1.4 = .010)