Shop by Category

Loading...

EDGE² SBN Feed, Speed & Diameter Compensation

Table 1: Effective Cutting Diameter (ECD)

| Depth of Cut (DOC) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Insert Diameter | .005 | .010 | .015 | .025 | .035 | .050 | .100 | .125 | .150 | .200 | .250 | |

| .500 | .099 | .140 | .171 | .218 | .255 | .300 | .400 | .433 | .458 | .490 | .500 | |

| .750 | .122 | .172 | .210 | .269 | .316 | .374 | .510 | .559 | .600 | .663 | .707 | |

| 1.000 | .141 | .199 | .243 | .312 | .368 | .436 | .600 | .661 | .714 | .800 | .866 | |

- Select diameter of tool to be used.*

- Determine Depth of Cut (DOC) to be used.*

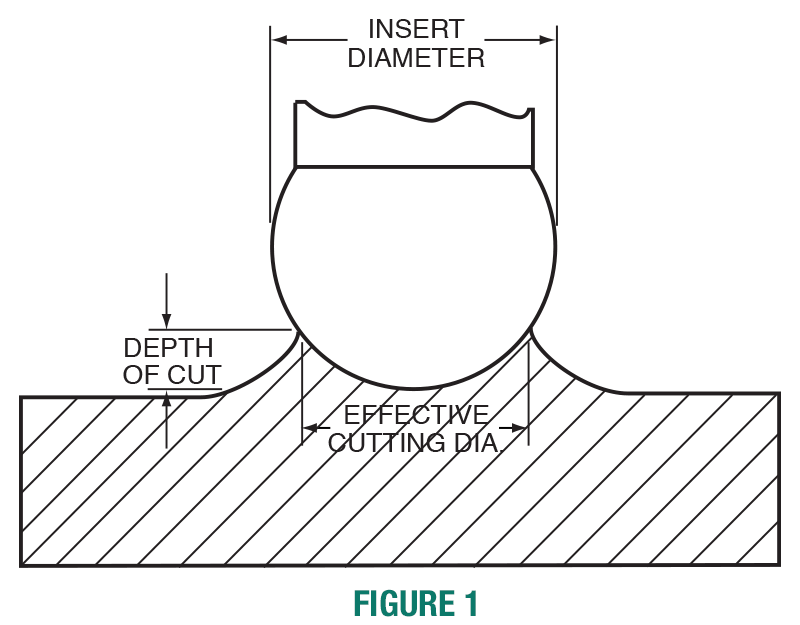

- Refer to Figure 1 and Table 1 to find the Effective Cutting Diameter (ECD).

- Refer to the Ball Nose Feed and Speed chart (PDF) to select the surface footage to be used (SFM).

- Calculate RPM using the ECD and SFM. (SFM x 3.82 / ECD = RPM)

- Refer to Table 2 to determine Feed Rate Adjustment (FRA).

- Refer to the Feed and Speed chart (PDF) to select Feed per Tooth (FPT). Calculate Inches per Minute (IPM). (RPM x FPT x 2 x FRA = IPM)

* For the cuts that are not strictly tip-cutting, but will use both the tips and sides of the SBN insert, pick an effective cutting diameter in between the ECD in the chart and the actual diameter of the insert. For example: If the ECD comes out to .210" with a .750" diameter insert, use .480" as your ECD when calculating RPM.

Table 2: Feed Rate Adjustment (FRA)

These feed rate multipliers are for applications involving tip-cutting only. For applications including side-cutting or slight/draft angles, lower the multiplier by 20-50%.

| Insert Diameter | ||||

|---|---|---|---|---|

| Depth of Cut (DOC) | 1/2" | 3/4" | 1" | |

| .005 | 5.0 | 6.1 | 7.1 | |

| .010 | 3.6 | 4.4 | 5.0 | |

| .015 | 2.9 | 3.6 | 4.1 | |

| .020 | 2.6 | 3.1 | 3.6 | |

| .025 | 2.3 | 2.8 | 3.2 | |

| .050 | 1.7 | 2.0 | 2.3 | |

| .075 | N/R | 1.7 | 1.9 | |

| .100 | N/R | N/R | 1.7 | |

Use multiple above to calculate adjusted feed rate.