Shop by Category

Loading...

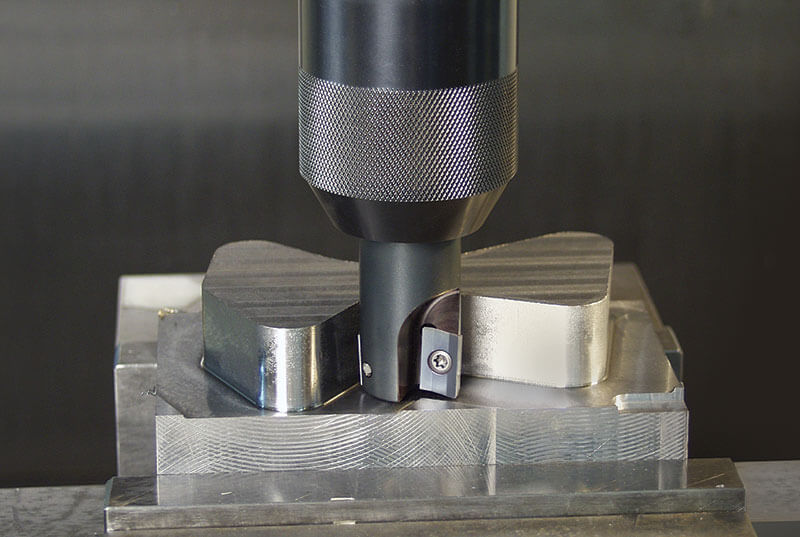

Square Shoulder Application Information

Square Shoulder Technical Considerations

- Always use anti-seize compound on screws.

- Thoroughly clean pocket at each insert change.

- Change insert screw every 10 inserts.

- Use the shortest-length tool holder (end mill holder) for maximum rigidity. The shank of the cutting tool should be up inside the machine spindle taper whenever possible.

- Use tool holders appropriate for roughing operations: end mill holders and power chucks are recommended; collets are not recommended.

Recommendations for 90-degree Milling

- Square Shoulder milling allows heavier Depths of Cut (DOC), but Dapra recommends that no more than 2/3 of the insert length should be engaged to reduce the chance for screw breakage.

- Although the cutter is capable of the heavier cut, take care to allow for the machine tool's capabilities in horsepower and rigidity.

- Utilize as much of the cutting edge per pass (DOC) as possible, to get the most metal removal within the insert's tool life.

- Feed rates should not go significantly below or above the recommended ranges (see recommended cutting speeds PDF), or premature failure can occur.

- Square Shoulder tools can not plunge; instead, use up to a 2° ramp angle for full diameter cut. Greater ramp angles possible with partial width cut.

- Climb milling is recommended whenever possible.

- Use the larger corner radii for the strongest cutting edge during roughing applications.

- Compensate for radial chip thinning (see chart) when Width of Cut (WOC) is less than 50% of the cutter diameter.

- Because our Square Shoulder tools cut a true 90°, they are a good choice for a wide range of finishing applications.

- Use Coarse Pitch cutters for slotting cuts or when cutting pressure needs to be reduced; use Fine Pitch cutters for lighter profiling cuts or when feed rates can be maximized.

- Most of Dapra's high-performance grades run best without coolant. Coolant in most milling applications creates a high potential for thermal shock, which can produce premature, and sometimes catastrophic, failure. Use air pressure to provide adequate cooling and chip evacuation.

- For long-reach applications, utilize the Carbide Core cutting tools for increased rigidity and reduced chatter.