11/28/2023 4:18 PM

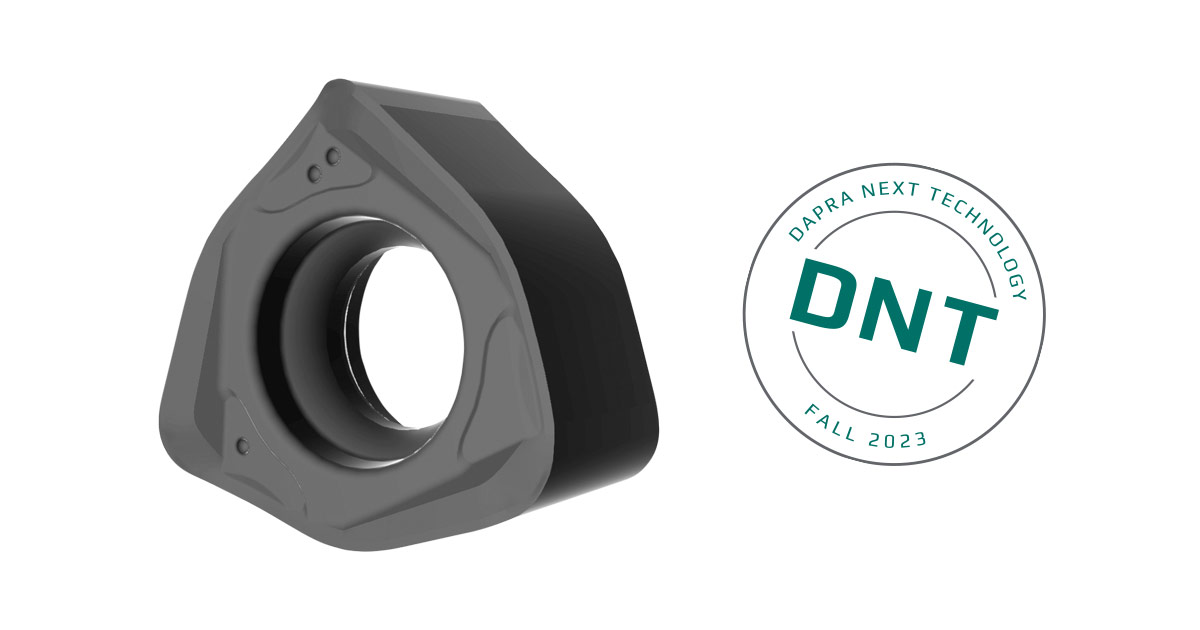

VAPOR High-Feed is now optimized for materials and applications that demand the DAPRA “D” geometry.

If you struggle to maximize metal removal rates when machining stainless steel and high-temp alloys, here's the news you've been...

Read More

If you struggle to maximize metal removal rates when machining stainless steel and high-temp alloys, here's the news you've been...

Posted By: brian@aspinwallhq.com

11/13/2023 1:00 PM

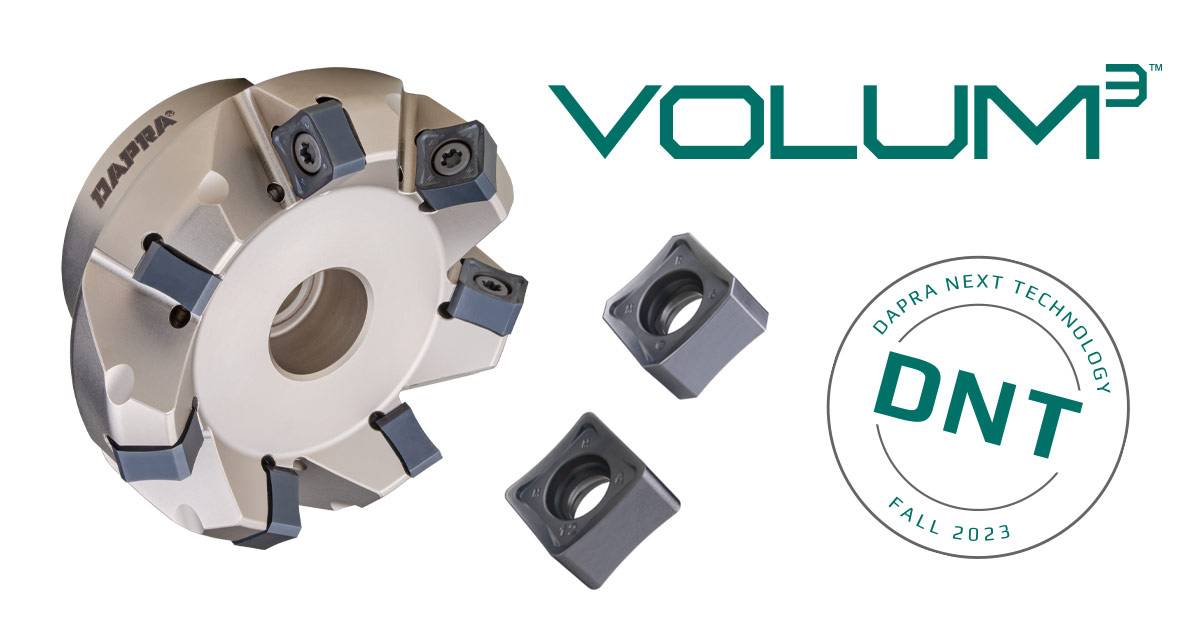

Are you ready to increase metal removal rates and optimize surface finishes with a single tool? We designed the VOLUM3™ indexable 45° face milling platform to maximize throughput and reduce machining costs in your most challenging applications.

Experience the...

Read More

Experience the...

Posted By: brian@aspinwallhq.com

4/26/2022 2:02 PM

Indexable milling provider Dapra Milling Solutions (Bloomfield, CT) and world-class workholding solutions provider ALLMATIC-Jakob Spannsysteme (Unterthingau, Germany) are pleased to announce the execution of a strategic collaboration agreement aimed at growing influence and market share in the North...

Read More

Posted By: pfaulk@dapra.com

12/14/2020 11:00 AM

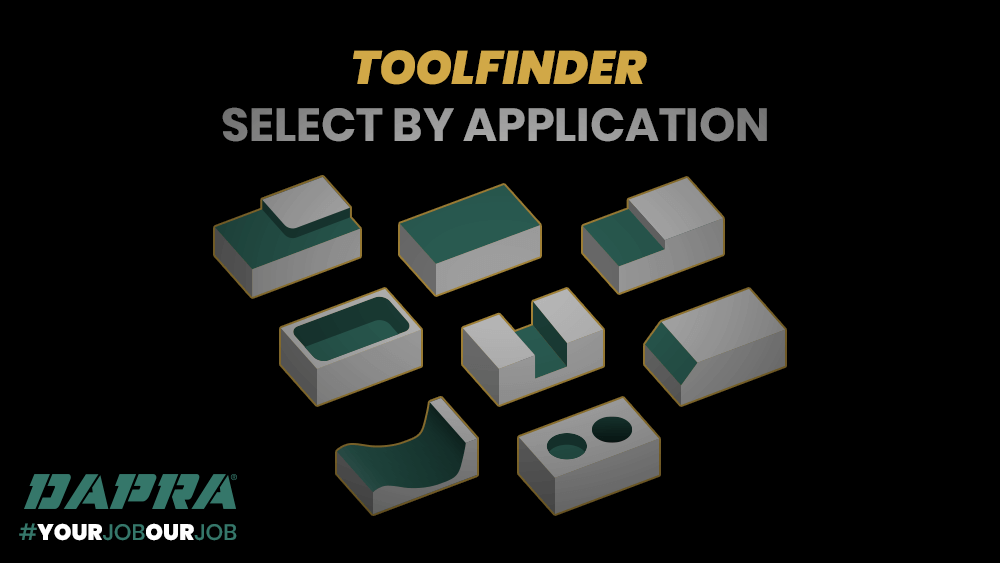

Save time finding the right cutting tool.

Selecting the right cutting tool for your milling application can be confusing, with hundreds of options at your fingertips from multiple suppliers – and often little guidance to help you through the process...

Read More

Selecting the right cutting tool for your milling application can be confusing, with hundreds of options at your fingertips from multiple suppliers – and often little guidance to help you through the process...

Posted By: brian@aspinwallhq.com

9/7/2020 4:30 PM

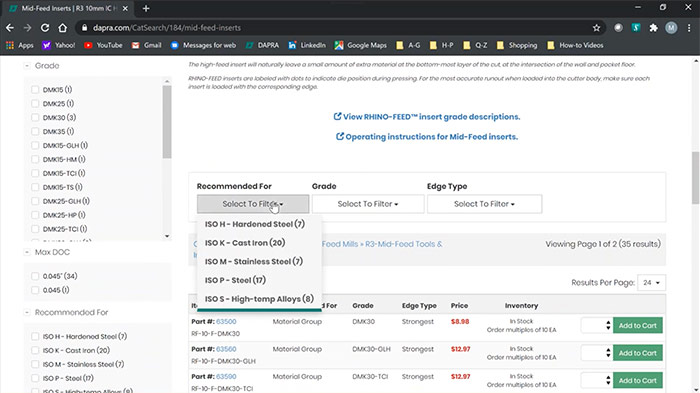

Recommended materials filtering and starting speed & feed charts are now available for many inserts.

Here at Dapra, we are constantly looking for creative ways to better support you and make it easier for you to run your milling...

Read More

Here at Dapra, we are constantly looking for creative ways to better support you and make it easier for you to run your milling...

Posted By: brian@aspinwallhq.com