Shop by Category

Loading...

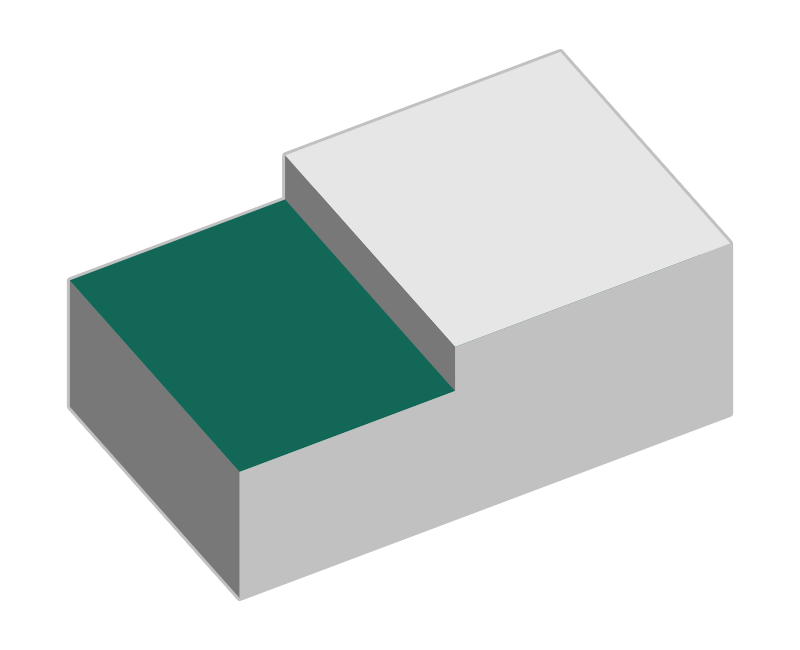

Face Milling Against a Shoulder – ToolFinder

When face milling against a shoulder, we recommend a 90-degree milling edge to allow close proximity to the shoulder and to minimize the corner radius left in the wall/floor transition.

If you have questions about the best tool choice and parameters for your application, please contact us.

Recommended Tooling for Face Milling Against a Shoulder:

EDGE² DSS Double-Sided 90° Square Shoulder Mills

- Double-sided inserts for lower cost per cutting edge

- General-purpose operating parameters

- Great for finishing work

- Suitable for all materials except nonferrous

- Replacement program for cutter bodies

- Single insert size (12mm)

- .031" and .062" corner radii available

APET/XPET Single-Sided 90° Square Shoulder Mills

- Aggressive cutting with the strongest inserts and enhanced clearance

- Excellent ramping capability

- Geometries and grades for all materials, including nonferrous

- Roughing focused, but good floor-finishing capabilities

- 3 insert sizes (10mm, 12mm, 16mm)

- Corner radii available from .015" through .120"

Need help with tooling selection or setting up your application?

Request free application assistance!