Interpolation is a fast, low-horsepower way to make larger-diameter holes.

By Michael Bitner

Product Manager, Dapra Corp.

This article originally appeared in Modern Machine Shop magazine.

Producing a large-diameter hole is a common application for many shops, and there are numerous methods that can be used to achieve the end result. However, there are often numerous obstacles to completing the process cost-effectively. Horsepower consumption is frequently a concern in these types of applications, especially on the more common 20 horsepower and below machine tools. These machines are capable of high speeds and feeds, but rigidity is sacrificed to the extent necessary to accomplish the quick movements. Using conventional means, making large-diameter holes is hard on the machine tool and the cutting tools involved. This fact has created the demand for a smoother method of making these holes that stays within the cycle times necessary to be competitive.

EWT Incorporated (Rockford, IL) has dramatically improved its hole-making capabilities utilizing helical interpolation. The concept was introduced to them by Dapra Corporation (Bloomfield, CT) in an effort to improve cycle times on a new part. EWT's owner, Don Busekros, explains, "We had an application for producing bases out of A2 tool steel for a new product line. These bases required significant metal removal, including producing a 3-1/2" dia. hole through the 2-1/2" thick part. Our initial thought was to drill a start hole approximately 1" in diameter, then to circular interpolate the remainder with a 1" end mill. Assuming our machine would take the cut at 0.200 per pass, we were looking at a cycle time of 15 to 20 minutes per hole. Using the helical method has reduced our cycle time to just over 5 minutes per hole, and it is much easier on my machine tool."

EWT Incorporated has saved an average of 50 percent or better on its cycle times during hole making by using helical interpolation with a square shoulder milling tool. The company used the 90-degree cutter because it was a cutter already used for other jobs.

EWT has gone from spending hours in larger-hole milling to just minutes. These gains were accomplished using Dapra's standard 90-degree milling tools, operating at high surface footages and feedrates with slight ramp angles (less than 1 degree). EWT found that it could save an average of 50 percent or better on its cycle times by moving away from conventional milling techniques and using the helical approach.

The company used the 90-degree cutter for its application because it was a cutter already used for other jobs. There are, however, different style cutting tools even better suited to this type of machining. Dapra has introduced a new product designed specifically for this kind of milling. The Felix®, a modular system designed to rough and finish holes up to five times the diameter in depth, can helically interpolate a hole in only one-third the time required for a standard milling cutter. Mike Bitner, regional applications manager with Dapra, explains, "A square shoulder mill is an acceptable choice for this type of milling since it is so commonly used for other applications. A shop that does not frequently perform this type of milling is just as well off to use it. However, a shop that has frequent applications for this type of milling would do better to invest in tooling that can take a more aggressive approach."

Consider the following case. EWT has a 5.5" dia. hole to put into a plate approximately 4" thick and is running the job on a 15-horsepower vertical machining center with a 40-taper spindle. Workholding rigidity is good, and the machine can run up to a 1.125" diameter indexable drill without stalling. As EWT sees it, it has four options:

- Drill with the indexable drill, then circular interpolate with an indexable end mill. This process will be difficult due to the length of the tool required and the radial cutting force involved; significant deflection is unavoidable. Light cuts will have to be taken with the end mill to avoid severe chatter and an undersize condition in the hole. Approximate cycle time would be 60 to 90 minutes.

- Drill with the indexable drill, then use multiple boring bars to increase the diameter one pass at a time. This process will work and yield a straight and accurate hole, but it will be time-consuming. It will also be expensive and will make chip evacuation more difficult. Approximate cycle time would be 45 to 60 minutes.

- Heavy-duty circular interpolation with a helical milling cutter. This method will consume a great deal of horsepower and, most likely, will not be possible without damage to a machine of this size.

- Helical interpolation — with or without initial drilled hole. For this application, a 3" dia. indexable milling cutter would work well right from the start. Predrilling the hole will aid in chip evacuation, but is not required for the success of this process. Depending on the style of cutting tool used, it will take roughly 65 to 200 passes to break through the part. While this sounds like a lot of cutting, the actual cycle time is relatively short. Approximate cycle time would be 10 to 22 minutes. Using the Felix®, the process can be executed with one cutting tool and run in a cycle time of 5 to 10 minutes.

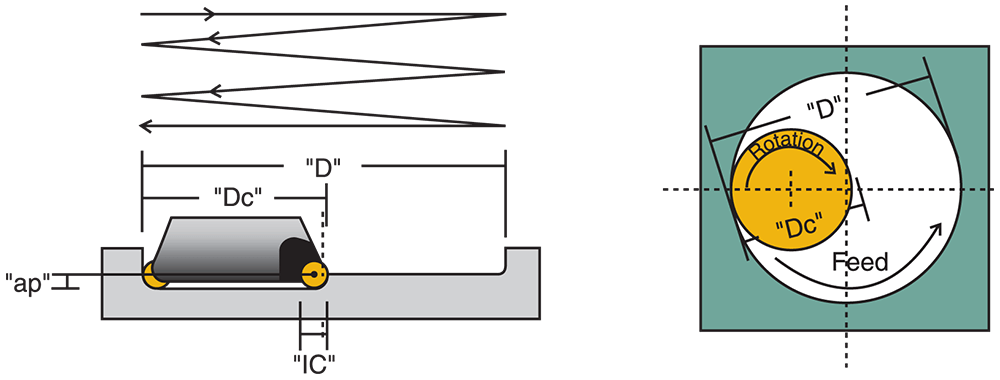

Taking circular interpolation to the next level – The cutter progresses downward in the Z-axis while simultaneously interpolating arcs using the X- and Y-axis. Continuous helical motion is executed until reaching the bottom of the hole. The helix amount may be adjusted to compensate for challenging situations such as long reach cutters, a poorly held workpiece, poor chip evacuation, low clearance angle on the cutting tool, etc. Lighter helix amounts can frequently make life easier for an operator when it comes to chip evacuation. The thinner, lighter chips produced by a smaller helix angle are more easily blown from the hole than the thicker, heavier chips produced by a large angle. The cutter shown in the diagram is approximately equal to one-half the hole diameter. A smaller cutter may be used, but will require multiple helixes to finish the hole.

Mr. Bitner also notes a consideration to take into account when trying this type of milling. "Chip evacuation is critical when helical interpolation is used," he says. "While operating in such a tight area, recutting of chips is a certainty, and steps must be taken to minimize this problem. Our first suggestion is typically high-pressure through-the-tool air blast, or high-pressure coolant, if the air is not available."

Mr. Busekros concurs, "We initially encountered some difficulties trying to evacuate chips using the machine tool's flood coolant. By equipping the machine with high-pressure air from an external line, we were much more effective in removing the chips, especially as the hole got deeper."

While helical interpolation isn't for everyone, it is a very viable alternative for many applications that involve hole making. Whether the difficulty lies in the hole size, depth, machine tool horsepower, or lack of rigidity in the setup, helical interpolation is an excellent solution. EWT knows this from experience. As Mr. Busekros says, "We have an advantage with this new knowledge in that we are now capable of high output efficiency, even on our lower output machinery. All it took was a change in our mindset to make it happen."

Dapra provides a variety of tools for helical interpolation, including 90-degree Square Shoulder mills.