Shop by Category

EDGE² SBN Twin-Edge Ball Nose System Guidelines

Achieve high-quality finishes AND use a Ball Nose insert twice!

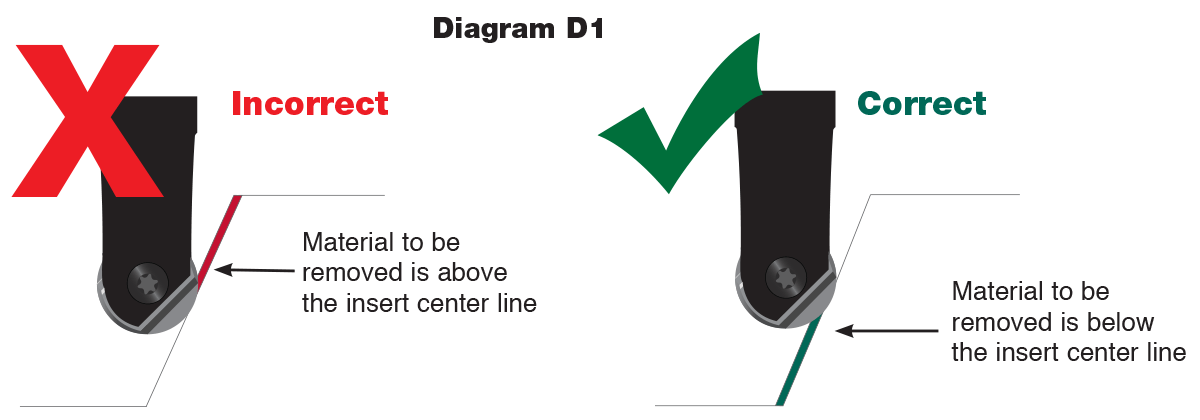

Achieving this cost savings requires adhering to a few simple application guidelines (see Diagram D1 below for examples):

Most Important!

Your SBN insert has a full 360 degrees of metal-cutting surface, but it must be used only 180 degrees at a time. All cutting must be kept at or below the insert center line to allow the cutting edges to perform correctly. Any attempts at cutting above the insert center line may result in failure, including insert and/or cutter damage.

Finishing

Use your SBN insert for finishing, preferably with a top-down program. In other words, start your cutting at the top of a part and profile around, slowly working your way down to the bottom (water-line programming/Z-level finishing). A raster-pass (lacing) cut may be used, but take care to leave less than .010" finish stock to avoid cutting above the insert center line. Best performance is achieved in tapered-wall work, but straight-wall finishing can be accomplished by using ONLY the "top-down" approach detailed below (see Diagram D1).

Semi-Finishing (Light Roughing)

Use your SBN insert ONLY with a top-down approach when semi-finishing or light roughing. Start your cutting at the top of a part and profile around, working your way down. DO NOT attempt to lace cut or raster, as rubbing on the back side of your SBN insert may occur (cutting above insert centerline), ruining the surface finish and potentially damaging your SBN insert.

Roughing

Your SBN insert is NOT suitable for roughing.

** In general, keep your cutting contained to the bottom 180 degrees of the insert – this allows two uses instead of one!