Shop by Category

Loading...

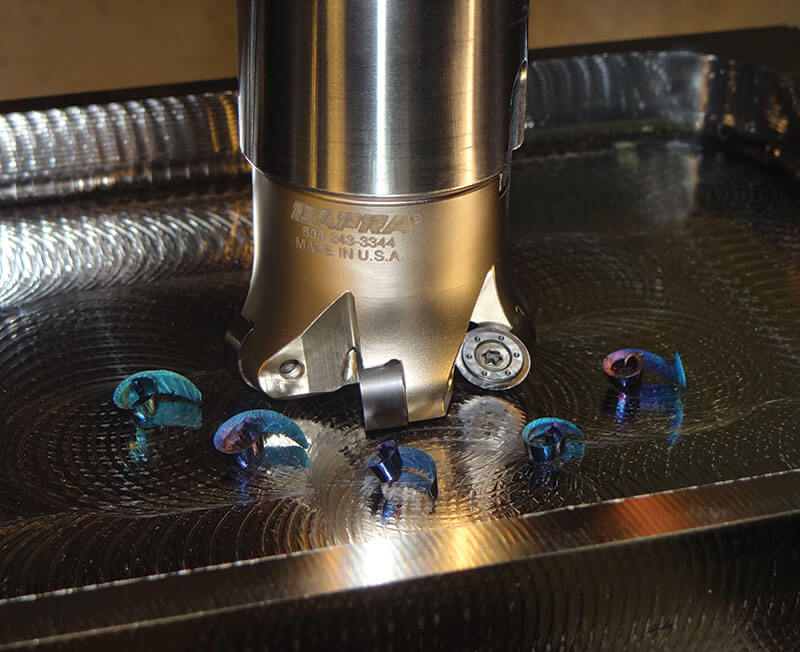

EDGE² DTB Application Information

Recommendations

- Tool is most appropriate for "Z-level" roughing; ramp to Depth of Cut (DOC) and clear entire level.

- Plunge milling is not recommended with DTB series cutters. Ramping (up to 2° max.) is recommended.

- Try to maintain at least 75% of the cutter diameter on the workpiece whenever possible. Hanging a cutter off to the side of your work is detrimental to tool life and performance.

- Width of Cut (WOC) should be 60-75% of cutter diameter whenever possible, creating a "scalloping" effect (end mills only) between passes, especially with longer-length tools.

- Round button inserts provide a very strong cutting edge and the ability to machine much closer to finish size. Utilize high feeds with light DOC to take advantage of these benefits. High metal removal rates will be achieved without high horsepower consumption.

- Use the Feed Rate Compensation chart to compensate for chip thinning that occurs with round inserts. This will provide for optimum metal removal rates and tool life; the lighter the DOC, the more critical feed compensation becomes.

Technical Considerations

- Always use anti-seize compound on screws.

- Change insert screw every 10 inserts.

- Use the shortest-length tool holder (end mill holder) for maximum rigidity; the shank of the cutting tool should be up inside the machine spindle taper whenever possible.

- Thoroughly clean pocket and screw at each insert change.

- Use tool holders appropriate for roughing operations: end mill holders and power chucks are recommended; collets are not recommended.