Search in Category

Filter Your Search

Best For

Best For

Carbide

Carbide

Edge Type

Edge Type

Grade

Grade

Insert Size

Insert Size

Radius

Radius

Shop by Category

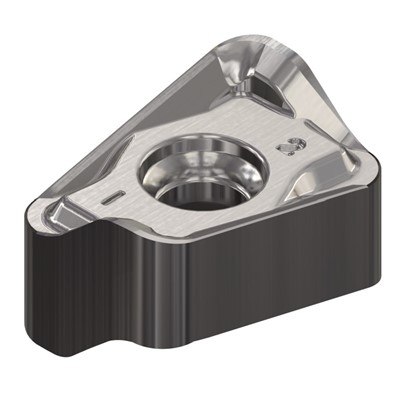

12mm Double-Sided Square Shoulder Inserts

Premium double-sided EDGE² DSS inserts provide twice the number of usable edges as a normal, single-sided APET/XPET Square Shoulder milling insert for cost-per-corner savings of up to 48%.

View DSS insert grade descriptions and selection information.

Reduce your cost per edge!

| Product | Cost per Corner |

|---|---|

| Standard competitor 2-edged APKT-style inserts | $7.00-$9.00 |

| Dapra standard APET/XPET inserts | $6.50 |

| Dapra NEW DSS inserts | $4.70 |

* All prices based on published list pricing. Actual end user pricing can vary. Dapra per-corner DSS pricing is with the free cutter replacement program included.

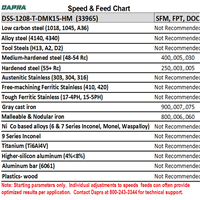

DSS-T inserts feature a high-strength cutting edge and are ideal for high-performance shoulder milling of most tougher steels and cast irons.

DSS-D inserts feature a sharper cutting edge ideally suited to high-shear shoulder milling of stainless steels, various exotic and nickel alloys, and low-carbon steels.

** Start with these filters – they will guide you to the right insert for your application **

| Item | Best For | Carbide | Edge Type | Coating | Radius | Price | Inventory | ||

|---|---|---|---|---|---|---|---|---|---|

|

33965 DSS-1208-T-DMK15-HM |

ISO | 3-Hardest (Wear Resistant) | Stronger | 1-High-temp Hard | .031” |

In Stock

Order multiples of 10 EA |

|

||

|

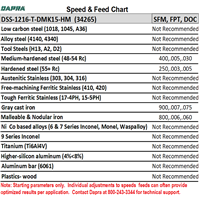

34265 DSS-1216-T-DMK15-HM |

ISO | 3-Hardest (Wear Resistant) | Stronger | 1-High-temp Hard | .062” |

In Stock

Order multiples of 10 EA |

|

||

|

33985 DSS-1208-T-DMK15-TS |

ISO | 3-Hardest (Wear Resistant) | Stronger | 2-High-temp Si | .031” |

In Stock

Order multiples of 10 EA |

|

||

|

34285 DSS-1216-T-DMK15-TS |

ISO | 3-Hardest (Wear Resistant) | Stronger | 2-High-temp Si | .062” |

In Stock

Order multiples of 10 EA |

|

||

|

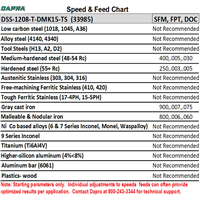

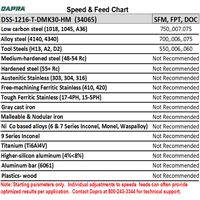

33592 DSS-1208-D-DMK30-HM |

ISO | 1-Toughest (Shock-resistant) | High-Shear | 1-High-temp Hard | .031” |

In Stock

Order multiples of 10 EA |

|

||

|

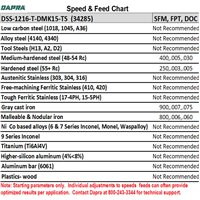

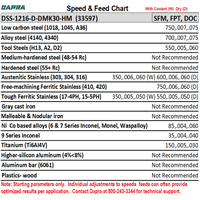

33597 DSS-1216-D-DMK30-HM |

ISO | 1-Toughest (Shock-resistant) | High-Shear | 1-High-temp Hard | .062” |

In Stock

Order multiples of 10 EA |

|

||

|

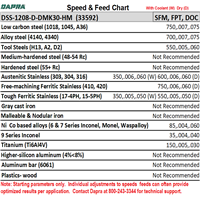

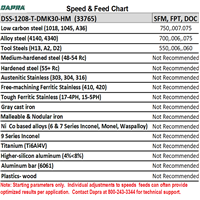

33765 DSS-1208-T-DMK30-HM |

ISO | 1-Toughest (Shock-resistant) | Stronger | 1-High-temp Hard | .031” |

In Stock

Order multiples of 10 EA |

|

||

|

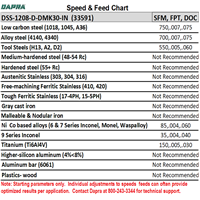

34065 DSS-1216-T-DMK30-HM |

ISO | 1-Toughest (Shock-resistant) | Stronger | 1-High-temp Hard | .062” |

In Stock

Order multiples of 10 EA |

|

||

|

33591 DSS-1208-D-DMK30-IN |

ISO | 1-Toughest (Shock-resistant) | High-Shear | 1-High-temp Hard | .031” |

In Stock

Order multiples of 10 EA |

|

||

|

33596 DSS-1216-D-DMK30-IN |

ISO | 1-Toughest (Shock-resistant) | High-Shear | 1-High-temp Hard | .062” |

In Stock

Order multiples of 10 EA |

|

- ISO

- 3-Hardest (Wear Resistant)

- Stronger

- 1-High-temp Hard

- .031”

- ISO

- 3-Hardest (Wear Resistant)

- Stronger

- 1-High-temp Hard

- .062”

- ISO

- 3-Hardest (Wear Resistant)

- Stronger

- 2-High-temp Si

- .031”

- ISO

- 3-Hardest (Wear Resistant)

- Stronger

- 2-High-temp Si

- .062”

- ISO

- 1-Toughest (Shock-resistant)

- High-Shear

- 1-High-temp Hard

- .031”

- ISO

- 1-Toughest (Shock-resistant)

- High-Shear

- 1-High-temp Hard

- .062”

- ISO

- 1-Toughest (Shock-resistant)

- Stronger

- 1-High-temp Hard

- .031”

- ISO

- 1-Toughest (Shock-resistant)

- Stronger

- 1-High-temp Hard

- .062”

- ISO

- 1-Toughest (Shock-resistant)

- High-Shear

- 1-High-temp Hard

- .031”

- ISO

- 1-Toughest (Shock-resistant)

- High-Shear

- 1-High-temp Hard

- .062”