Choose the best indexable milling tooling the first time – every time

Save time finding the right cutting tool.

Selecting the right cutting tool for your milling application can be confusing, with hundreds of options at your fingertips from multiple suppliers – and often little guidance to help you through the process.

ToolFinder provides simple recommendations to assist you with tooling selection. Start by choosing your basic application or required tool type. We'll guide you through cutter and insert selection with easy-to-use filters and speed and feed data. The video link below provides a walkthrough.

ToolFinder Start by either selecting from a list of common milling applications (shoulder milling, facing, profiling, 3D profiling, etc.) or the type of tooling you are looking for (shoulder mills, high-feed, copy mills, or ball nose/backdraft). You'll then be presented with some application considerations and a summary of the best tooling for the job.

Cutter & Insert Filtering

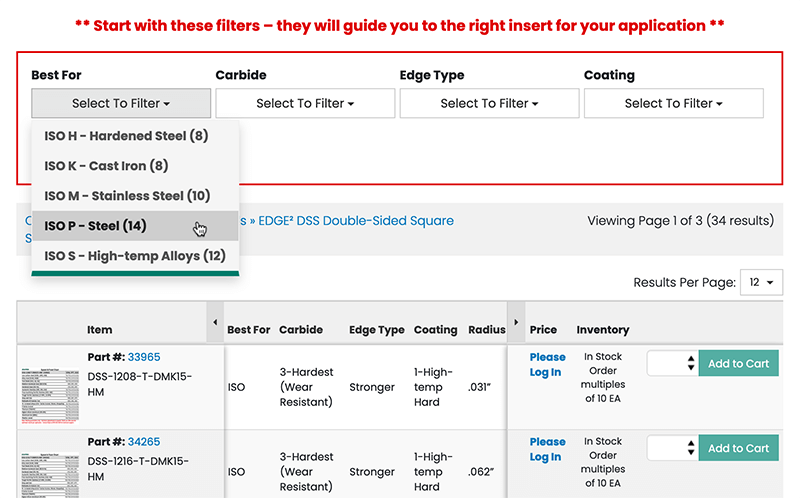

Once you land on a cutter or insert category page, look for the red outlined box for filters to help you narrow down your options.

For inserts selection, filters include things like material/ISO group (use the "Best For" filter), carbide, edge type, coating, and corner radius or cutting diameter.

Depending on the type of body, filters for cutters can include cutting diameter, effective length, arbor diameter, number of fluters, and cutter body material.

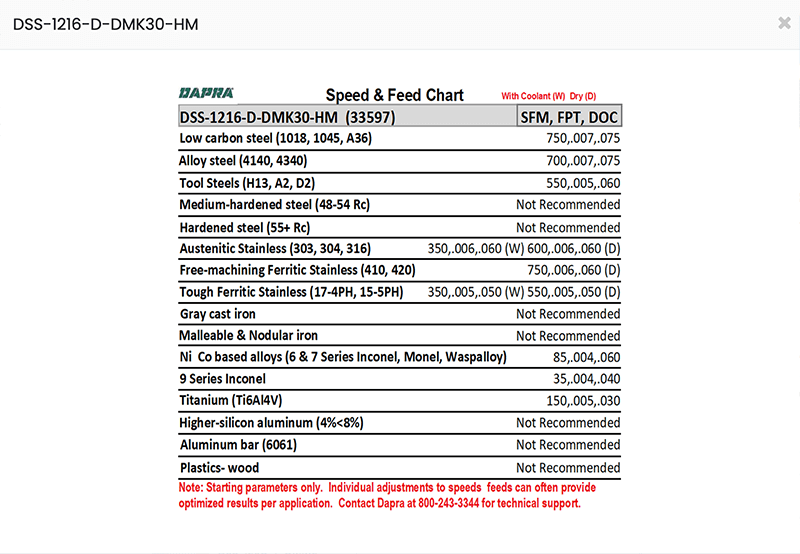

Speed & Feed Charts

We also now offer starting speed & feed charts (including depth of cut recommendations) for each individual insert that show the operating parameters that will work for a specific insert in a given material group. These show as an image associated with each item – click on the chart to enlarge it.

ToolFinder is a great starting point for anyone looking for an automated approach to cutting tool selection. Rest assured, our applications specialists are also still here and always available to help you select the best tooling and parameters. We are here to support you from tool selection to the spindle. Click here to request assistance.