Machining Tips for Mold & Die Shops

Plunge. Lead in. Profile. Lead out. Repeat until reaching final depth. Profile milling does not have to be this inefficient! As you’ll see here, whether you are helixing, contouring, pocketing or slotting, high-feed ramping allows you to rough in your part profile much more quickly.

Using indexable tooling from Dapra, you can achieve MRR that rivals high-efficiency milling – without the cost of solid carbide end mills. This flexible, ultra-fast, economical approach also allows you to run at the same parameters in long-reach applications with a 2x or 3x length-to-diameter ratio.

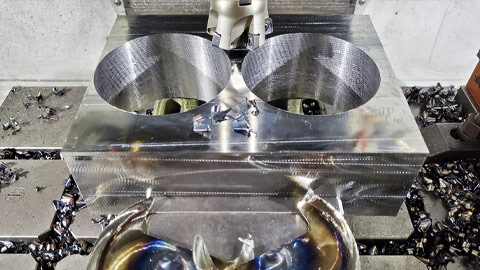

A smarter approach to machining chase pockets

Have you ever struggled to consistently achieve straight walls and accurate sizing when machining mold insert chase pockets? Learn a solid approach to roughing, semi-finishing, and finishing the walls and floor of a deep, straight-walled pocket, with an eye toward helping you cut cycle times and reduce costly zero cuts.

Efficiently machining large-diameter holes

Forget time-consuming starter holes and step cuts. High-feed helixing can shorten cycle times for large-diameter hole making to never-before-seen levels – even on a 40-taper machine.

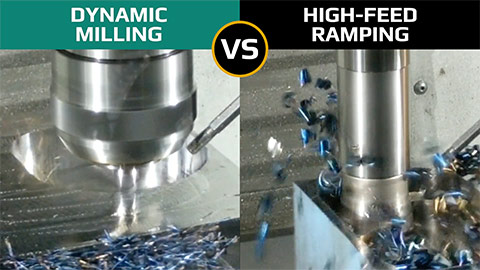

High-efficiency milling vs. high-feed ramping

Dynamic milling with a solid carbide end mill is all the rage, but you may be able to match – or beat – those removal rates and save significant money on tooling by ramping with indexable high-feed tooling.

Tips for more efficient 3D milling

3D milling involves a variety of tools and tool paths. In less than 5 minutes, this video demonstrates three different 3D shapes, what tools we recommend for machining, suggested for path generation for each.

Get more tech tips!

Join our email list or follow our social channels for regular tech tips. Need assistance with your application? Contact one of our technology specialists to review your parameters.

Unattended high-feed milling to repurpose a forge die – Finkl FX2 hammered steel

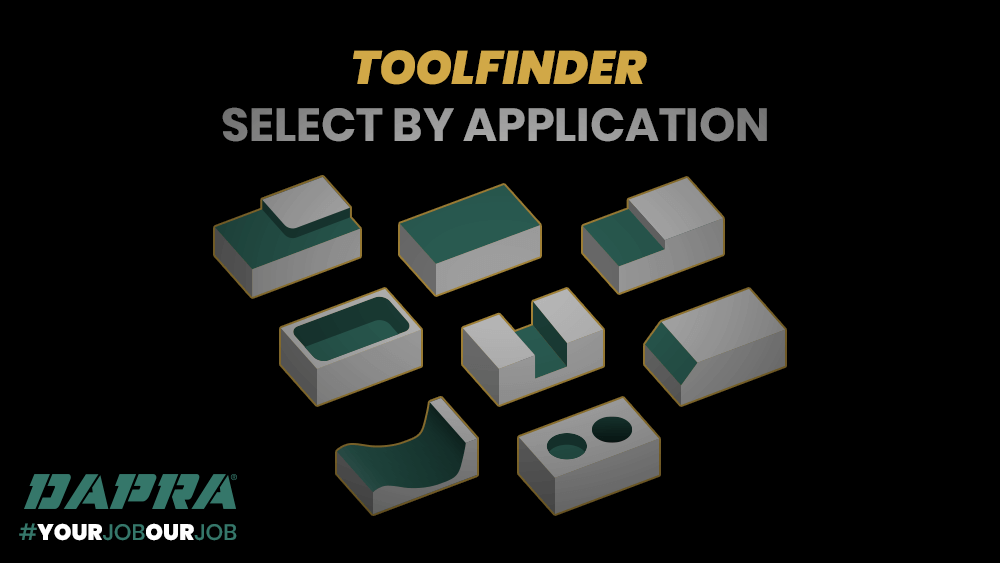

Unattended high-feed milling to repurpose a forge die – Finkl FX2 hammered steel Choose the best indexable tooling the first time – every time

Choose the best indexable tooling the first time – every time Analyze This: Examining a cutting tool’s performance values, not just its cost, reveals the true efficiency of machining processes. Via MoldMaking Technology

Analyze This: Examining a cutting tool’s performance values, not just its cost, reveals the true efficiency of machining processes. Via MoldMaking Technology