More profitable contour milling with indexable, high-feed tooling

High-efficiency (Dynamic) milling with a solid carbide end mill is all the rage, but you may be able to match – or beat – those removal rates and save significant money on tooling by ramping with an indexable high-feed tool. In this quick demo, we high-feed ramp an outside profile to 3.5" depth. Our Heavy-Feed shell mill cuts the 4140PH material at 287 IPM, even at 4.5" gage length, and on a Haas 40-taper machine!

This common contour milling application demonstrates several advantages of high-feed ramping over high-efficiency milling:

- Equal or even better metal removal rates

- Substantially lower tooling cost

- Index inserts quickly with no change in tool size

- Axial tool pressure for better cutting stability

- Mill to deeper depths without compromising productivity

Dapra is more than just a tooling provider. We work closely with shops of all sizes to help optimize milling efficiency and profitability, from their tooling choices to the way they attack critical applications.

Have questions about implementing this approach?

Get more tech tips!

Join our email list or follow our social channels for regular tech tips. Need assistance with your application? Contact one of our technology specialists to review your parameters.

Choose the best indexable tooling the first time – every time

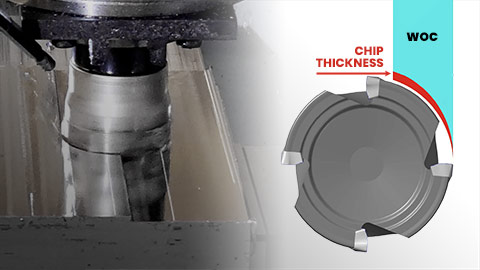

Choose the best indexable tooling the first time – every time Maximize feed rate with radial chip thinning

Maximize feed rate with radial chip thinning